Posted By

MMS

on 2018-07-22

20:30:55

|  Re: Poll_What kind of "dual floppy desktop" style you like? Re: Poll_What kind of "dual floppy desktop" style you like?

Yepp, based on my experience intercontinental postage of such a big block could go up to 100-120$.

and it is only the postage yet.

As a conclusion (if may want to produce here, but there is a possible market in US/Canada), then design should be

1) lightweight but strong (to not bend under the weight of the monitor)

Actually the metals really show better strenght/weight ratio, but the composite materials win

unfortunately not easy to produce, not easy to handle, and rather expensive.

Interestingely balsa wood would be perfect, very light weight and seems stronger than polypropilene

(or plywood)

Unfortunately wood does not look well next to Commodores

https://en.wikipedia.org/wiki/Specific_strength

http://www-materials.eng.cam.ac.uk/mpsite/interactive_charts/strength-density/basic.html

2) Compact design during shipping, do not ship big air inside

It should be a more assembly like design (foldable design or IKEA style screwing) to reduce the air shipped inside

--> it would greatly reduce size of package -->reduce shipping cost (together with the lightweight material)

Keep thinking

UPDATE:

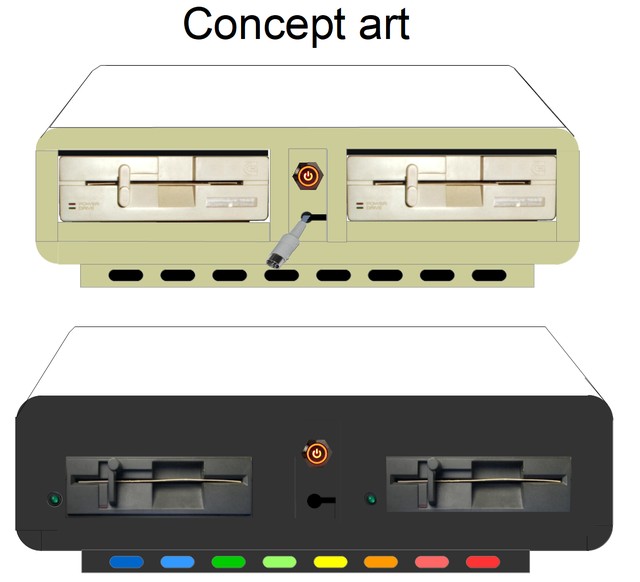

Concept art of the two versions. I choose a kind of 70s' 80s' retro futurism design (hopefully you will see it too :-) )

1) 1541-II compatible: foldable side design with front inserts from plywood + thick top cover from solidwood.

Spray painted ~PANTONE Warm Gray 3C (any RAL t o match with 1541/II? ), or keep top's original solidwood color (acacia?) just lacquered/oiled while the rest kept spray painted

2) 1551/1541 Compatible: foldable side design + complete front + thick top cover from solidwood

1551: Spray painted with matte RAL 9004 Signal Black

1541: Spray painted with matte RAL 1001? RAL1015?

I consider holding the front with strong magnetstripes, but maybe a bad idea close to the floppy drives

Sides and center two could be foldable with 90°hinges, made from 10-12mm (0.5") plywood. This sould easily withstand 15kg weight.

-To withstand monitor weight and prevent movement of hinges, the sides and inner parts with be strenghtened with thin metal rods

-Top part will be a robust thick material

-The center part can be used for leading cables, or as a slot for SD card based system. It uses IEC only, then it will communicate on the same IEC cable daisy chained internally. For 1551 version, the SD's IEC cable can go out on the same hole as the 1551 connector cable.

-There will be some ventillation hole above the floppy drives to prevent overheating

-Rear panel silent PC fan is planned, probably USB powered to keep it intenationally useable

-Both the IEC cable and the 1551 cable would come out at the front to the machine. it would require shorter cable, and would give the feeling the Plus/4 is like a keyboard :-) The same hole could be used for the monitor video cable.

-To prevent CRT monitor interferences, internally the top and the sides will be covered with self adhesive thin copper foil (used for electric guitars too)

-Front button would be there only for design. It would be very straightforward and elegant to switch on and off the device with a button (handle the power strip (?)) , but then safety and high voltage testing would come into picture I cannot manage at this hobbist level.

Also worth to mention the localization. I would have some troubles to get US or UK type mains cable and extention lead here.

-The floppy drives will be positioned with wooden spacers and will be fixed with rubber bunges to hooks.

-There is an idea to add an expandable handle to the base, like for the suit-cases

-Certainly there will be rubber feets (I consider 6 or 8 support to have a robust anti-bending design), but design not considered yet, probably something related to metal too, as I am a metal fan :-P

(all these ideas would some up to something "not cheap"), but would be options to have no handle, or cheaper material could be used for top.

The biggest challenge could be the top.

Plywood cannot be used, although strong enough, the nice shape cannot be formed. Balsa wood surface could be compressed under weight, despite very flexible.

From solidwood the more robust ones could be considered, Acacia, oak, eucalyptus. 18mm - 25mm thickness. Pine is out of question, too weak.

These solid woods expensive and heavy, though we have the advantage to keep the original wood nive aesthetics (though not fully retrofit).

(plastics I even do not consider: they are complex and expensive to be produced and too weak compared to wood)

I am especially curious how do you like the 1551/1541 compatible version's style.

I would hide the majority of these old floppy drive to get a more clean and stylish surface. Not to mention the original drive's surface is not so even.

On the other hand I can add the same color scheme on the base (with some more idea it could be even backlit too, but would mean more complexity and more electronics and more complex woodwork).

Please let me know your opinitons. If you do not like at all, it is also an option (a really possible option), and may in itiate some redesign here.

I like futuristic retro design, but maybe I am alone with this.

I am now looking for the materials locally and online, hopefully in 2 months I will have a prototype to show.

UPDATE2:

Today I visited few places to check raw materials and speak with some guys know better wood tah me.

12mm playwood is still bending a little (though at that size as the side panels may not so much), but the bigger problem is their tendency to warp after long term use.

After speaking with some experts, a non-formaldehid MDF (without foil) could be a nice option (next to solid wood), as pretty strong, very smooth surface, well paintable after preparation, and can be well formed with tools, still keeping well the screws (not like particle board). HDF used for kitchens with matte anthracit color could be nice too. but these are very heavy in this size and thickness, heavier than solid wood.

I found some very nice beech wood panels and supportive part for steps, really perfect. But price-wise it would be the double cost, and would be a crime to cover that nice material with paint even it is has Commodore RAL code :-D

But I hardly believe anyone will be interested to purchase a wooden looking Desktop from EU, as anyone can do one himself from pine or any other wood (though it would not have the same properties, but eh... foldable sides not required if you make it locally, and you could save a lot on the special hinges too)

Question (next to the hiding stuff (that would make 1541 and 1551 same looking drive), do you have any idea what to put on that big flat black surface?

Probably a big Commodore logo from silver letters would generate some copyright stuff, right?

UPDATE 3:

The more expert I speak, the more it will become evident, that it should be from E1 class formaldehid free MDF, with proper water based painting outside (RAL color).

Still, the sales factor of such a expensive, handcrafted part is questionnalble.

It should offer something more, and special.

I was thinking about the 3 cartridge expander unit. It exist for 3 slots of C64 cartridges, but as far I as I see, it was never released in the form of Plus/4 cartridge.

It would be very nice addition to a C16: you could add 64K RAM cartridge + 2pieces of 1551s without huge space requirement behind the machine (like good old ZX81 with 16KB extension :-) )

On the other hand, such a fixed position of the machine VS the "Floppy Desktop" would be really unfavourable.

So it could work only with a flexible extension cable.

Till today noone could manage to create such an expansion port extension cable for C64 and C+4.

This is strange.

If you think a little, it is really not logical, why with flex cable expansion port extension does NOT work. The more I think, then more I see it is just about quality of the cable/connector, and the loss of signals (maybe diue to no amplification).

Just check the SCSI standard: it uses TTL level signals, and support MUCH higher data speeds than the ones may happen in a Commodore (SCSI 1 minimum: >5MBPS)

SCSI cable lenght could be up to 9 meters. Internally it uses only a 50 pin flex cable.

PATA/133 with the 80 PIN cheap connector could transfer 33MB/second with less the 50cm long cable. 50cm with a simple felx cable!

If you thinka little, such speeds could never happen with an 1551, and I have questionmarks related to the 64K RAM expansion too (what cound happen with the 64K expansion)

IEEE-488 standard (used by C= PETs too) could also handle 1 megabyte per second, though it used 16 pin connectors, and well shielded cables, but allowed also several meters long cables too. It als used TTL level and logic.

Thinking a little, there should be no any real cause, why a longer (flex cable) could not manage C= signals.

It should be the shielding and twisted wire technology.

PATA/122, EIDE could manage stable loading with high speed when the 80pin cable with twisting wire introduced

(one ground wire next to each data line -->no interference between signals)

Before that, sometimes the ATA was arkward and buggy, especially little lobnger cables.

Unfortunately, PATA utilizese 80 lines, but only 40 is usaable, but Plus/4 expansion port had 50 lines (lincluding ground and +5V), data line is 41 pin.

(so that cheap connector and cable is not enough for our purpse)

So THEORETICALLY, if a proper 50 real line twisted wire (properly shielded) cable could beused, then with a proper connector at both ends the longer Expansion port extender is possible (for one or more extrernal cartridge connection)

|